### University of Bristol’s Innovative Polymers Launch into Space for Examination

In a revolutionary endeavor, four cutting-edge polymer materials created by researchers at the University of Bristol are undergoing testing in one of the most extreme environments known to humanity—outer space. These advanced materials were launched on a SpaceX rocket and will be subjected to rigorous evaluations aboard the International Space Station (ISS), experiencing unprecedented exposure to the harsh conditions of space. The aim is for these polymers to become the next wave of robust materials for space exploration.

These innovative polymers, two of which integrate state-of-the-art nanoparticles, are engineered to endure the tough environments encountered in space. Each of the four materials is reinforced with carbon fibers, significantly boosting their strength and durability. These materials are not only designed to outlast current alternatives but are also made with sustainability in mind, allowing for recyclability at the end of their lifecycle. This forward-thinking strategy could transform the materials utilized in spacecraft, supporting long-term space missions and promoting circular space technologies.

### Testing on the Bartolomeo Platform

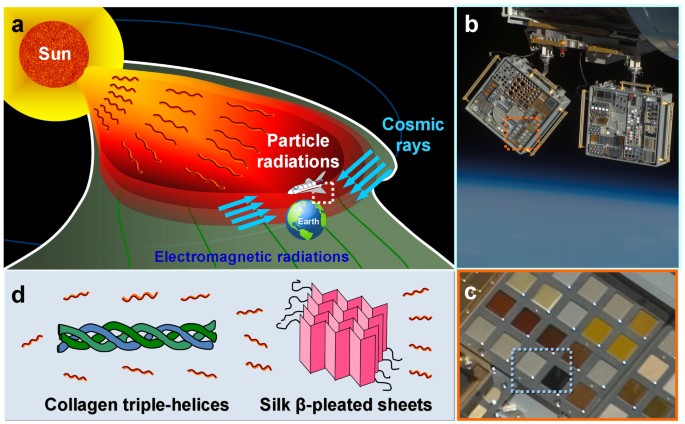

The polymers from Bristol have been dispatched to the Bartolomeo platform, positioned at the front of the ISS. During the next 12 to 18 months, the materials will be exposed to up to 9,000 orbits around Earth, presenting a challenging testing backdrop. The polymers will withstand extreme conditions, including drastic temperature variations from -150ºC to +120ºC, encounters with high-velocity space debris, and substantial exposure to electromagnetic radiation. Furthermore, they will confront hostile atomic oxygen in the vacuum of space, which can deteriorate materials at a molecular level.

### Tackling the Challenges of Space

Creating materials fit for space is no trivial task. Ian Hamerton, a respected polymer and sustainable composites researcher at the [University of Bristol’s Composites Institute](https://www.bristol.ac.uk/people/person/Ian-Hamerton-b3d6ab4a-54e4-41a8-8eaa-d03d2893891a/), articulated that space represents the “most challenging environment” for the development of new materials.

“You are putting your materials knowledge, expertise, and creativity against extreme temperature variations, mechanical stress, radiation, high-speed impacts, and more,” Hamerton emphasizes. Once these materials are utilized in space, repairs or maintenance become nearly impossible, so the polymers must be capable of withstanding prolonged exposure without any servicing—a vital requirement as off-world exploration and long-duration space travels become more prevalent.

### Factors Influencing Space Materials

The space environment subjects materials to various punishing factors:

1. **Temperature Variations**: The drastic shifts in temperature can cause materials to undergo thermal expansion and contraction, leading to deformations and fractures.

2. **Space Debris**: Moving at speeds seven times greater than that of a bullet, space debris poses a significant threat to materials, particularly during impacts with spacecraft.

3. **Electromagnetic Radiation**: Materials must withstand the high-energy solar and cosmic radiation common in space, which can undermine molecular stability.

4. **Atomic Oxygen**: The ISS orbits within the thermosphere, where atomic oxygen can erode surfaces, making strong anti-erosion resistance crucial for these polymers.

If these new polymers successfully navigate these challenges, they may facilitate the creation of more durable space components that play a significant role in extended space exploration initiatives.

### A Cooperative Research Endeavor

The materials currently under scrutiny are the product of over five years of dedicated effort by a collaborative group of researchers at the University of Bristol. Alongside Hamerton, early-career researchers, postgraduate students, and several Aerospace Engineering undergraduates have contributed to the space material initiative. The active participation of undergraduates in final-year research projects has been key in cultivating future specialists in aerospace materials research.

This hybrid methodology, integrating experienced insights with fresh viewpoints, ensures that the materials’ design benefits from both cutting-edge research and innovative ideas across various educational levels.

### Promoting Sustainable Space Exploration

Among the most progressive elements of this study is the emphasis on sustainability. Present-day spacecraft materials often present challenges at the end of their lifecycle, as they can be hard or impossible to recycle. By embedding recyclability into the process, the team from the University of Bristol is advancing space travel toward a more sustainable, resource-efficient future.

As humanity aims for ambitious endeavors such as a continued lunar presence and crewed missions to Mars, longer-lasting and recyclable materials will be critical for reducing costs, minimizing waste, and ensuring that spacecraft can function over extended periods. The polymers from the University of Bristol could therefore have extensive implications for spaceflight logistics in the decades ahead.

### Conclusion

The polymers engineered by the University of Bristol team are set to be crucial in the future of sustainable space exploration. Their resilience, augmented with nanoparticles and carbon fibers, alongside their recyclability, renders them ideal candidates for spacecraft navigating the extremes of space. Over the coming year