**Transforming Carbon Dioxide into Carbon Composites: A Milestone in Sustainable Materials Innovation**

In a time that demands urgent action to reduce carbon emissions and combat climate change, scientists from the University of Delaware and Washington University have devised a pioneering method that converts carbon dioxide (CO₂)—a significant greenhouse gas—into robust carbon nanocomposites. This innovative technique not only tackles environmental issues but also offers substantial possibilities for transforming materials utilized in sectors like transportation and construction.

The initiative is led by Kelvin Fu from the University of Delaware and Feng Jiao from Washington University, both located in the United States. Their study marks a crucial advancement in harnessing CO₂ as a valuable raw material while diminishing reliance on fossil-based substances.

—

### **The Mechanism of the Process**

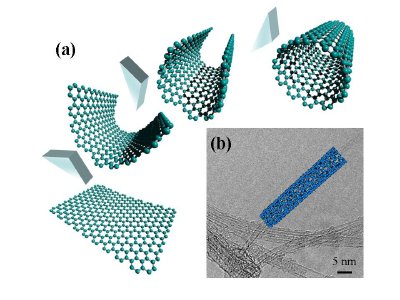

The method commences with the electrochemical reduction of carbon dioxide into carbon monoxide (CO). This is accomplished through electrolysis, a well-known process that dissociates molecules into their fundamental elements. The carbon monoxide is subsequently channeled into a thermochemical reactor, where steel wool acts as a catalyst to transmute the CO molecules into carbon nanotubes (CNTs).

Carbon nanotubes are nanostructures celebrated for their outstanding mechanical strength, thermal resilience, and electrical conductivity. Their integration into materials has typically been hindered by high production costs—an issue that Fu and Jiao’s method aims to resolve.

Once synthesized, the carbon nanotubes are utilized in a 3D printing technique to produce thermoset carbon nanocomposites. These nanocomposites, sporting an impressive 38% by weight composition of carbon nanotubes, blend high performance with sustainability. The researchers assert that this increased nanotube concentration is vital for optimizing CO₂ sequestration and conversion into usable products.

—

### **A Revolutionary Approach to Carbon Nanotube Manufacturing**

Historically, carbon nanotubes are generated using fossil fuel-based feedstocks through energy-intensive methods, making them both expensive and environmentally burdensome. The researchers’ approach mitigates these drawbacks by streamlining the production process and tapping captured CO₂ as the primary resource.

The economic analysis conducted by the team suggests that the expenses associated with carbon nanotube production using their technique could decrease by as much as 90% compared to traditional methods. This significantly diminishes the obstacles for widespread acceptance of CNTs and ushers in new opportunities for their use.

—

### **Uses in Transportation and Construction**

The newly engineered carbon nanocomposites boast remarkable strength, thermal durability, and lightweight qualities, making them a formidable alternative to conventional construction and transportation materials like aluminum and titanium. These properties render them perfect for:

1. **Automotive and Aerospace Engineering:** Lightweight yet strong nanocomposites have the potential to lower vehicle weight, improving fuel efficiency and cutting emissions. Manufacturers in the aerospace and automotive sectors might opt for these materials to comply with stricter environmental standards without sacrificing performance.

2. **Construction Materials:** Carbon nanocomposites might transform building endeavors by providing improved features, including long-lasting durability, resistance to environmental wear, and thermal insulation.

3. **Energy Storage and Electronics:** Though not directly linked to construction or transport, the electrical conductivity of CNTs paves the way for uses in energy storage (e.g., batteries) and electronic components, thereby broadening the applications of these materials.

—

### **Environmental and Economic Advantages**

Beyond producing high-performance materials, this method could significantly contribute to global efforts aimed at lowering carbon emissions. By converting CO₂ waste generated from industrial and energy sectors, this approach embodies the principles of a circular economy—transforming a pollutant into a valuable asset.

“In light of the surging global demand for carbon nanocomposites, our carbon dioxide-to-nanocomposite process holds the potential to significantly influence global carbon emission reduction initiatives,” the researchers noted.

Additionally, the method’s capability to produce essential materials at lower costs aligns with the economic goals of industries striving to shift to sustainable methods without incurring exorbitant costs.

—

### **Consequences for a Sustainable Future**

This advancement closes the gap between environmental stewardship and industrial scalability. By turning a principal greenhouse gas into advanced, highly sought-after materials, Fu and Jiao’s technique epitomizes an exciting fusion of carbon capture innovation and state-of-the-art engineering.

As the global community continues to prioritize sustainability, breakthroughs like this have the potential to reshape how industries manage CO₂, materials science, and energy efficiency. Furthermore, with the capability to significantly reduce dependence on fossil fuels, it offers a constructive method to transform harmful emissions into products vital to contemporary society.

While hurdles persist—especially concerning the escalation of this process for widespread industrial application—the prospective benefits render it a hopeful answer to some of the most urgent challenges of the 21st century. If successfully implemented on a global scale, this innovation could simultaneously foster economic development and environmental accountability, ushering in a new chapter of sustainable materials innovation.

In a world where carbon is frequently viewed as an adversary, this process serves as a reminder that