# Centimeter-Sized Flexible Diamond Films: Innovations and Potential Applications

A significant advancement in materials science has been achieved as Chinese researchers successfully create centimeter-sized flexible diamond films. Employing a novel method of chemical vapor deposition followed by a straightforward exfoliation technique using Scotch tape, they have managed to navigate substantial hurdles in diamond film manufacturing. This innovative approach presents vast potential in various high-tech fields, including heat management in electronic devices and as a potential semiconductor material.

## Diamonds: From Brittle to Flexible

Diamond is famously known for its remarkable hardness and brittleness, characteristics that render it both unique and difficult to work with. However, when formed as thin, continuous films on substrates such as silicon, diamonds exhibit unexpected flexibility.

Materials scientist James Butler, formerly with the US Naval Research Laboratory, clarifies, “Diamond is really a continuum of materials.” The flexibility is primarily due to the grain boundaries present within the diamond structure when produced as thin films. During their growth, smaller grains are supplanted by larger ones, resulting in fewer grain boundaries and increased brittleness. Yet, during the early stages of thin film formation, the existing grain boundaries function as strain energy dissipation sites, allowing for a degree of flexibility that bulk diamonds do not possess.

## A Simplified Process: Scotch Tape Exfoliation

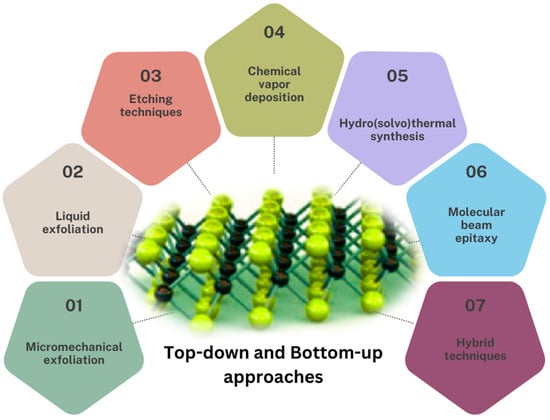

Diamonds can be fabricated on silicon substrates via chemical vapor deposition. Nevertheless, the process of detaching these films—often several thousand atoms in thickness—without causing damage has historically posed a significant technical challenge. Standard techniques typically involve mechanical polishing, followed by plasma or chemical etching of the silicon, which are both labor-intensive and risk damaging the fragile membrane through wrinkling or cracking.

The success achieved by the Chinese researchers, led by Zhiqin Chu from Hong Kong University along with graduate student Jixiang Jing, stemmed from an unexpected discovery. While aiming to enlarge their diamond film samples, a small broken piece demonstrated natural peeling from its silicon substrate. This prompted the researchers to explore a mechanical peeling approach. Drawing on methods similar to the renowned Scotch tape exfoliation of graphene, they exposed a film edge, initiated a new crack, and effortlessly peeled it away using adhesive tape—remarkably simple yet efficient.

Chu recalls the moment as a breakthrough. “It seemed crazy, because we had this idea that diamond films were fragile… but we took this one piece, created a new crack to get the edge exposed, then we took some tape and it was done.” Inspired by graphene’s discovery, the team transformed what some might view as an adhesion flaw into a successful detachment strategy.

## Potential Applications: A Bright Future

The successful peeling of centimeter-sized flexible diamond films unlocks new opportunities for utilization in various industries, including electronics and sensors. One of the most immediate commercial prospects is their application in electronic cooling systems. Diamond’s ultrahigh thermal conductivity renders it an exceptional thermal pad for dissipating heat in high-performance semiconductor devices. Moreover, the films’ ultra-flat surfaces align well with existing semiconductor manufacturing techniques.

Looking ahead, researchers envision the potential for diamond films as semiconductor materials. Diamonds are already acknowledged as semiconductors with a wide bandgap, high electronic mobility, and excellent thermal characteristics—properties crucial for high-power electronic applications. By experimenting with doping techniques, these films could be transformed into conductors or endowed with unique traits for next-generation electronics.

James Butler, who was not involved in this research, acknowledges the promise of the membranes while remaining cautious about semiconductor uses. “Finding suitable dopants in diamond would really open up diamond electronics, but no one’s found that yet after many years of research,” he observes. Nevertheless, he believes these membranes could serve niche functions in sensors, including acoustic wave transducers.

## Challenges and Future Work

Although this breakthrough signifies substantial progress, challenges persist. As Butler points out, the major difficulty lies in identifying appropriate doping materials for diamond to effectively utilize it in semiconductor technology. Doping entails introducing impurities into the crystal lattice to modify electrical characteristics, and unlike other materials such as silicon which have established doping methods, diamond poses significant challenges in this area.

Nonetheless, the ability to grow and exfoliate flexible diamond films relatively easily paves the way for scientists and engineers to investigate applications that were once hindered by production constraints. Progress in diamond thin-film technology may also catalyze advancements in optics, wear-resistant coatings, and biomedical devices.

## Conclusion

The achievement of flexible diamond films at the centimeter size using a deceptively simple Scotch tape exfoliation technique marks a significant leap in materials science. By harnessing the unique physical properties of diamonds, these films show extraordinary potential for transforming cooling systems for electronic devices and, with additional research, as components in high-performance semiconductor technologies.

While challenges such as effective doping persist, the demonstrated flexibility and scalability of this work have reignited interest in diamond films and their prospective applications. Often, innovation emerges from unforeseen moments, and in this case, it has unlocked exciting possibilities.