# **Chemically Recycling Perovskite Solar Cells: A Path to Reduced Costs and Enhanced Sustainability**

### **Introduction**

Perovskite solar cells have consistently been viewed as a promising substitute for conventional silicon-based photovoltaics. These materials offer the potential for high efficiency and cost-effective manufacturing, but worries about their longevity and environmental repercussions have hindered their broader implementation. Researchers from Sweden and the United States have now found that chemically recycling perovskite solar cells could address these issues, significantly lowering costs and positioning them as strong competitors to traditional silicon solar panels.

### **A Breakthrough in Recycling Perovskite Solar Cells**

A research group headed by **Feng Gao** at **Linköping University, Sweden**, has showcased an innovative method for **affordably and repeatedly recycling perovskite solar cells**. This technique facilitates the extraction and recuperation of perovskite materials to produce **new high-efficiency solar cells**. Importantly, the recycling process is **eco-friendly**, predominantly utilizing **water-based conditions**.

A vital element of the research stems from a **techno-economic assessment and life-cycle analysis** conducted by **Fengqi You’s team at Cornell University, US**. Their findings reveal that recycling perovskite solar panels **reduces expenses** by decreasing material and production costs, thereby enhancing the economic feasibility of the technology.

### **The Growing Need for Solar Recycling**

Since their debut in **2009**, **perovskite solar cells** have garnered substantial interest due to their **affordable manufacturing and exceptional energy conversion efficiency**. Nonetheless, ensuring their **durability** and **sustainability** remains a significant hurdle.

Current **silicon solar cells**, which dominate the global marketplace, are recognized for their **impressive longevity**—numerous panels installed around **2000** are now nearing the end of their **25-year lifespan**. However, the **recycling process for silicon panels is still inefficient and expensive**, with many being discarded in landfills.

Perovskite materials, which are now starting their **commercial rollout**, provide an opportunity to incorporate **recycling-ready technology right from the start**. The innovation from the Linköping team presents a potential **sustainable approach** for the forthcoming generation of photovoltaics, tackling the issues linked to perovskite solar technology.

### **Understanding Perovskite Solar Cells**

The term **perovskite** describes a class of materials with an **ABX₃ structure**. In the context of the **Linköping team’s perovskite** formulation:

– **A** = an organic cation (**methylammonium, formamidinium, or a combination**)

– **B** = lead (**Pb²⁺**) cations

– **X** = iodide (**I⁻**) anions

When **sunlight** strikes the perovskite layer, it energizes electrons into a **higher energy state**, creating positively charged **holes**. If both electrons and holes make it to the **electrodes**, an **electric current** can be generated.

A **primary concern** in perovskite solar technology is the inclusion of **lead**, which may present toxicity risks. Moreover, the **shorter lifespan** of perovskite cells in comparison to silicon could exacerbate the **solar waste issue**. Therefore, developing **efficient recycling methods** is critical for the responsible rollout of perovskite solar panels.

### **A Cleaner Approach to Recycling**

While several **perovskite recycling techniques have been developed**, they frequently depend on **harmful solvents** like **dimethylformamide (DMF)**. In contrast, the **Linköping team** has introduced a **green, environmentally friendly method** that guarantees nearly complete material recovery.

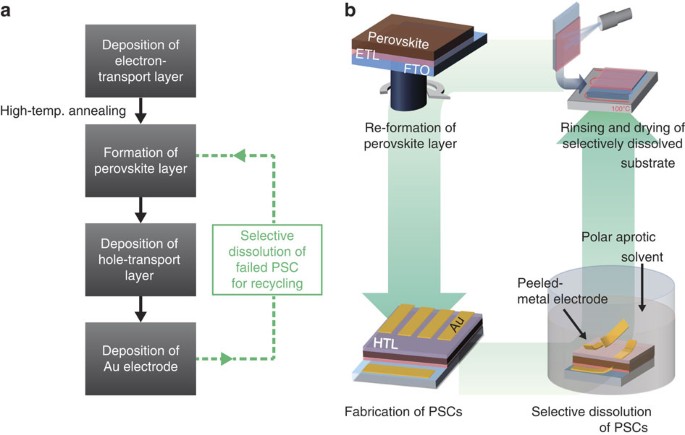

Their **recycling process** includes these fundamental steps:

1. **Heating to 150°C** – Softens and eliminates the **protective encapsulant**.

2. **Using ethyl acetate** – A **green organic solvent** that efficiently removes **spiro-OMeTAD**, a hole transport material.

3. **Dissolving the perovskite** – Employing a **water-based solution** with **sodium acetate, sodium iodide, and hypophosphorous acid** at **80°C**.

– **Sodium acetate** dissolves lead salts.

– **Iodide ions** assist in preserving the perovskite structure.

– **Hypophosphorous acid** restores iodide from iodine oxidation.

With this **low-impact recycling method**, the team adeptly **recovers over 99% of the materials** from used devices. Even more remarkably, new solar cells produced from the **recycled materials** retain their **efficiency and stability** across **five full recycling cycles**.

### **Economic and Environmental Benefits**

Once the **recycling method** was successfully