Title: A Breakthrough in Mercury-Free Lithium Isotope Separation – Essential for Advancing Nuclear Fusion

As the global community moves closer to harnessing nuclear fusion as an endless, sustainable energy source, the need for particular lithium isotopes—especially lithium-6—is expected to increase significantly. Historically, the extraction of lithium-6 from its more prevalent counterpart lithium-7 relied on toxic and environmentally harmful mercury-based methods. However, a novel technique pioneered by scientists at ETH Zürich in Switzerland and Texas A&M University in the United States presents an encouraging, cost-effective, and non-toxic alternative that could transform the acquisition of the essential lithium-6 isotope required for fusion reactors.

The Lithium Isotope Challenge

Lithium, a soft metallic element highly sought after for batteries and advanced energy solutions, primarily appears in two stable isotopic variations: lithium-6 (Li-6) and lithium-7 (Li-7). Among these, Li-7 constitutes around 93% of the lithium found in nature, leaving Li-6 at a mere 7%. Although this minor isotope may appear limited, it is vital for nuclear fusion processes—particularly in deuterium–tritium (D–T) fusion, regarded as the most energetically efficient fusion reaction currently under investigation.

Tritium (T), a radioactive hydrogen isotope, is not readily found in nature and needs to be generated on-site within fusion reactors. This is where Li-6 becomes essential. When hit with high-energy neutrons, Li-6 can generate tritium through a nuclear interaction, making its availability crucial for ensuring ongoing D–T fusion.

A Hazardous History

Up until now, the main technique for isolating Li-6 from Li-7 employed mercury amalgams—a method effective in isotope discrimination due to the differing solubilities of isotopes in mercury, but extremely harmful to humans and the environment. The toxicity and extensive usage of mercury in this process resulted in its prohibition in the United States over six decades ago, fueling a search for a safer alternative.

Introducing Vanadium Oxide: An Isotope Selective Filter

The recently introduced technique revolves around utilizing a porous variant of vanadium oxide (V₂O₅), which serves as an electrochemical filter. This material creates channels within its structure that can selectively absorb lithium ions. When an electric voltage is applied, these pores preferentially attract lithium-6 ions more strongly than lithium-7, achieving effective separation.

“If you visualize the connections between V₂O₅ and lithium as a spring,” shares Andrew Ezazi, the co-first author of the study, “you can perceive that Li-7 is heavier and more apt to break away from the spring, while the lighter Li-6 reverberates less and thus remains more tightly bound.”

The process functions similarly to a desalination system: lithium-infused water—often sourced from industrial waste streams including fracking and oil extraction—is passed through the vanadium oxide filter. Here, Li-6 ions are captured, while Li-7 flows through the electrochemical system with greater ease. This gentle yet precise method greatly decreases the necessity for toxic reagents or extreme operational conditions.

Scalability and Multi-Cycle Enrichment

One of the most exciting features of this innovative approach is its scalability. The research team has already initiated efforts to enhance the system’s efficiency for industrial purposes. This process isn’t a one-time operation; it gains effectiveness through a multi-cycle strategy. As Li-6 builds up with each pass, the approach enables gradual enrichment.

Under optimal conditions, enrichment can reach 30% Li-6 within just 25 cycles and up to 90% after 45 cycles—a remarkable improvement over previous mercury-based techniques. While the initial single-pass enrichment may appear modest at 15%, the cumulative effect over multiple passes offers a practical pathway to achieve fusion-grade Li-6.

Environmental and Economic Benefits

Beyond its non-toxic characteristics, the vanadium oxide method is particularly low-cost. Vanadium oxide is affordable, easily accessible, and has excellent electrochemical properties ideal for selective ion separation.

“This is an affordable, non-toxic electrochemical filter that can not only isolate lithium ions from complex solutions but also manage the relative migration rates of the lithium isotopes through the filters,” remarks Abby Kavner from the University of California, Los Angeles, who was not part of the study.

Pathway to Fusion Energy

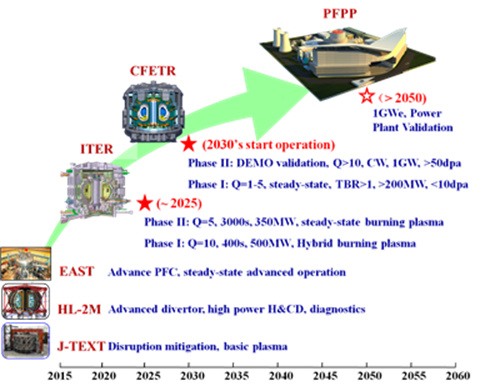

Should nuclear fusion evolve into a feasible clean energy source—as projects like ITER and private initiatives such as Helion Energy are investigating—the demand for substantial Li-6 production will be critical. Some projections indicate that fusion fuel requirements could reach several tonnes of Li-6 daily. This new separation method has the potential to fulfill that demand sustainably, responsibly, and economically.

Conclusion

The creation of a mercury-free system for lithium isotope separation utilizing vanadium oxide could signify a pivotal advancement in the pursuit of fusion energy.