A group from Humboldt University of Berlin, spearheaded by Michael Kathan, has created an innovative light-driven molecular motor that generates catenanes from hydrocarbon strands independently of templates. This breakthrough addresses a major obstacle in molecular machine design: harnessing directional movement to shape three-dimensional molecular forms.

In contrast to conventional approaches that depend on prearranged starting materials and templated reactions, this system employs mechanical rotation to fabricate entangled configurations that are thermodynamically non-viable. Henry Dube from Friedrich-Alexander University remarks that this represents a new frontier in chemical research, linking nanoscale mechanical actions with the formation of chemical structures. The method facilitates the synthesis of various interlocked constructs.

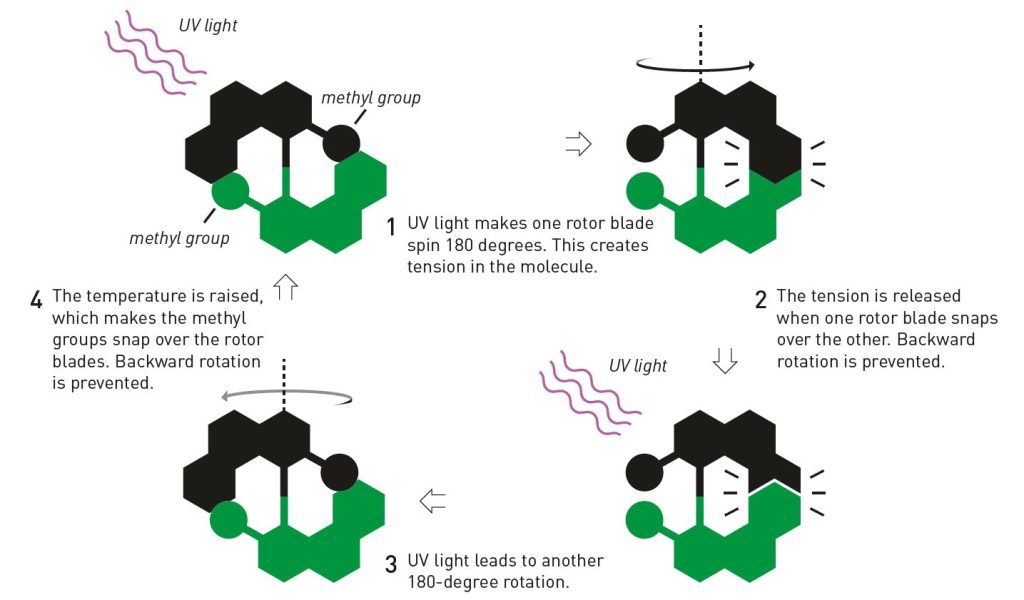

The motor functions through a double-bond axle that rotates unidirectionally when exposed to light, completing a 180° cycle through photochemical and thermal reactions. This process winds macrocycles into helices. A subsequent olefin metathesis reaction finalizes the structure to create the catenane, with ester-based anchors being cleaved to release the product.

Tommy Wachsmuth from Kathan’s group emphasizes the selectivity and kinetic stability of their motor, which is based on first-generation Feringa motors. The technique allows for the formation of catenanes from materials that are generally unsuitable for current templating methods.

Kelong Zhu of Sun Yat-Sen University notes that this presents new possibilities in molecular nanotechnology, with each 180° rotation providing precise and selective topological control.

Analyst Ho Yu Au-Yeung from the University of Hong Kong compares it to molecular-level stitching performed by a sewing machine, underlining the effectiveness of energy-driven synthesis for interlocked molecules. The team plans to expand the approach to include knots and rotaxanes while enhancing efficiency and scalability. Michael Kathan aims to produce interlocked structures that exhibit no indications of their fabrication process, achieving a type of ‘molecular craftsmanship.’