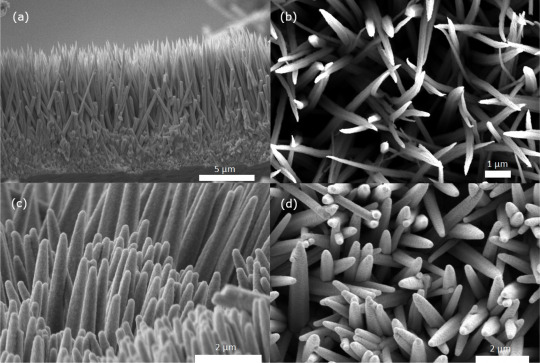

In a laboratory at the University of the Basque Country, a mat of deep black nanoneedles absorbs light like a sponge. The material, copper cobaltate shaped into needle-like formations and topped with an ultra-thin aluminum-doped zinc oxide film, has now shown solar absorption of up to 99.5% during high-temperature, wide-angle evaluations. For concentrated solar power systems, where mirrors direct sunlight into a central tower, achieving such near-total darkness is not merely a novelty. It serves as a financial advantage.

The team’s research, published in Solar Energy Materials and Solar Cells, addresses a persistent challenge for central-receiver systems: durable coatings that remain extremely dark at elevated temperatures and over steep angles of incoming light. The black silicon coatings currently applied on towers achieve around 95% absorption. Carbon nanotube mats can approach 99%, but they tend to degrade due to heat and humidity, often requiring protective coatings that diminish their optical effectiveness. The copper cobaltate nanoneedles from the Basque group, particularly when conformally coated with conductive AZO, seem to strike a balance between optical performance and stability.

Why an Additional 0.5% Black Could Be Significant

In central receivers, each small fraction of a percent lost to reflection translates into heat that doesn’t contribute to the molten salts within. These salts store energy for generation after sunset, which is the hallmark advantage of tower-based concentrated solar power. The researchers found that the AZO overcoat not only maintains ultralow reflectance from ultraviolet through near-infrared but also preserves high absorption even when light strikes at large off-normal angles, simulating real heliostat fields where sunlight arrives from various directions.

This angle robustness is crucial. CSP plants are not delicate optical platforms; they endure harsh conditions, including wind and dust, requiring coatings to perform from early morning to midday extremes. The team also assessed emissivity up to 600 C and recorded unusually high hemispherical values, exceeding 0.9 for AZO-coated samples. High emissivity can enhance radiative heat loss, presenting a potential efficiency tradeoff at receiver temperatures, but in tower designs operating under extreme solar concentration, improved solar absorptance typically surpasses mid-infrared losses. The cautious view: field tests will need to confirm the true systemic benefits once factors like dust, cyclic heating, and weather are taken into account.

“The more effective we can make absorbing materials, the more competitive our systems will become, thereby creating opportunities for this type of energy,”

stated Iñigo González de Arrieta of EHU’s Thermophysical Properties of Materials group. He and his team indicate that their lab is among a select few capable of high-temperature thermo-optical characterization, including bidirectional reflectance and emissivity under air. The visual is easy to imagine: vertically aligned nanoneedles standing like dense, velvet-black bristles on an alloy plate, their AZO covering functioning as a transparent conductor in the visible spectrum while absorbing infrared.

Beyond Carbon Nanotubes, with Considerations

Carbon nanotubes have become synonymous with extreme blackness, yet they encounter challenges on towers. The results from the EHU team highlight this limitation clearly, pointing to copper cobaltate’s refractory spinel structure as a better high-temperature foundation. The role of AZO is twofold: it provides an anti-reflection effect in the visible range and maintains absorption in the infrared thanks to free-carrier interactions. The authors argue that this combination retains blackness across both spectrum and angle. Their analysis also demonstrates thermal stability in air up to 600 C, a vital requirement for receiver service temperatures anticipated in third-generation CSP programs.

“Carbon nanotubes absorb about 99% of the light, but they cannot be utilized on solar towers.”

This remark from the EHU release captures the frustrations in the field. Even if a coating appears ideal visually, it must be producible at scale, adhere to receiver alloys, resist abrasion and fouling, and fit within maintenance schedules. Here, the study is both cautious and hopeful. The AZO layer was applied using atomic layer deposition, a gold-standard method for uniformity, but it is typically slow for large components. Actual towers will require process pathways that reconcile precision with throughput, or alternative conductive oxides that can be applied at scale without sacrificing the angle-independent blackness observed in the lab. Durability against desert dust, salts, and steam will be crucial.

Nonetheless, the advantages are evident. If a coating consistently converts 99.5% of focused sunlight into heat at the receiver, tower plants can operate at higher temperatures with a smaller aperture area or maintain output with fewer heliostats. This could help drive levelized costs closer to targets established by DOE initiatives. Collaborators from UC San Diego, including Renkun Chen, are already engaging with U.S. partners regarding potential deployment. Whether that progress endures through policy fluctuations remains uncertain. What appears less ambiguous is the optics: these nanoneedles are exceedingly black and exceptionally robust.