# Innovative Catalytic Approaches in Alkene Production: A Significant Step Toward Addressing Long-Standing Issues

Alkenes, commonly known as olefins, play a vital role as chemical intermediates that greatly influence manufacturing sectors on a global scale. These unsaturated hydrocarbons are fundamental building blocks for the production of common materials such as plastics and synthetic rubber, as well as intricate compounds like pharmaceutical ingredients. Despite their importance, the synthesis of alkenes has posed challenges, often necessitating extreme reaction conditions, restricted starting materials, and occasionally resulting in unwanted byproducts.

Recent progress in catalytic techniques is now leading to more effective and sustainable methods for alkene synthesis. Two novel strategies, independently developed by scientists from the National University of Singapore (NUS) and Eindhoven University of Technology, present creative pathways for producing alkenes under gentle conditions while enhancing yield and selectivity. These advancements promise benefits for both small-scale synthetic chemistry and large-scale industrial applications. Let’s delve into the science behind these revolutionary methods.

## 1. Photocatalytic Conjugate Addition: Broadening Alkene Synthesis Avenues

The initial novel technique incorporates a photocatalytic process that utilizes visible light to facilitate the creation of complex alkenes from precursors such as carboxylic acids, alcohols, and alkanes—substrates that have historically been problematic in alkene synthesis. This groundbreaking approach fills a crucial void in organic synthesis by enhancing both selectivity and adaptability.

### Mechanism of Action

“To address the drawbacks of conventional methodologies, we have implemented a photocatalytic conjugate addition step that not only improves selectivity but also broadens the substrate range,” stated **Hao Zeng**, the lead investigator at NUS.

This photocatalytic method consists of a two-step, single-pot reaction. The first phase is a radical addition that employs energy from visible light to create a saturated carbonyl intermediate through interaction with vinyl ketones as radical acceptors. After the saturated intermediate is generated, a Norrish type II photoreaction—a well-established photochemical process involving carbonyl compounds—triggers selective fragmentation, culminating in the formation of the target alkenes.

The technique is notably versatile, allowing for the synthesis of a diverse array of alkene molecules, including α-alkenes (with double bonds at the terminal carbon of the chain) and internal alkenes (with double bonds situated within the carbon chain). Importantly, the method exhibits high compatibility with compounds featuring multiple functional groups, making it particularly suitable for late-stage diversification in pharmaceutical development.

### Significance for Organic Chemistry and Pharmaceuticals

According to Zeng, this method may have far-reaching consequences in organic chemistry, particularly in pharmaceutical synthesis where the sequential addition of alkenes is essential. It creates opportunities for selective transformations that were previously considered impractical with traditional reagents and could facilitate the construction of complex molecules—potentially lowering costs and minimizing environmental implications.

Nonetheless, as highlighted by **Ming Joo Koh**, another organic chemist at NUS, the method has its constraints. Specifically, it may not be ideal for creating stereochemically defined alkenes, which are particularly vital in certain pharmaceutical contexts. Nevertheless, this technique serves as a robust complementary resource to current alkene synthesis methods.

## 2. Improved Fischer–Tropsch Conversion for Long-Chain Alkenes

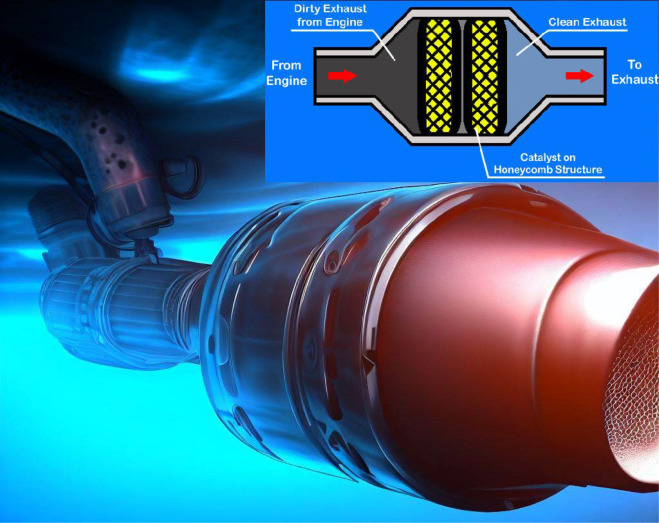

While Zeng’s team focused on diversifying alkene synthesis using unconventional precursors, researchers at **Eindhoven University of Technology** aimed at enhancing the efficiency of existing alkene production—specifically, honing in on the Fischer–Tropsch (FT) process. This established method converts synthesis gas (syngas)—a blend of carbon monoxide (CO) and hydrogen—into hydrocarbons, including alkenes. Nonetheless, common issues include low efficiency and the formation of unwanted byproducts like carbon dioxide (CO₂).

The team, led by **Emiel Hensen**, tackled these challenges by introducing a ‘phase-pure’ iron carbide catalyst, which is engineered to optimize active catalytic phases while minimizing the generation of iron oxides. The incorporation of phase-pure catalysts significantly enhances the efficiency of converting syngas into valuable long-chain alkenes while decreasing CO₂ emissions.

### A Breakthrough Catalyst for the Fischer-Tropsch Process

“In traditional Fischer-Tropsch techniques, iron catalysts frequently lead to substantial CO₂ production, which not only diminishes yield but also results in a loss of valuable carbon,” explained Hensen. His team’s precisely engineered catalytic system achieves CO conversion rates at lower temperatures than those typically seen in the FT process, while also eclipsing the performance of cobalt-based catalysts, which have long been viewed as the benchmark.

The primary innovation lies in curbing side reactions that yield unwelcome byproducts. By concentrating on the selective generation of alkenes, Hensen’s team has accomplished catalytic activities that are “one to two orders of magnitude higher” than