### Innovations in Frost-Resistant Surfaces: A Cutting-Edge Method Utilizing Tiny Cones and Graphene Oxide Coatings

Frost poses a significant obstacle in everyday life, whether it involves clearing the windshield on a cold morning or, more critically, when it impacts essential infrastructure like outdoor power lines, aircraft, and heat exchangers. The repercussions of frost accumulation in these scenarios can be both financially burdensome and perilous to safety. Now, a recent technological advancement appears to deliver a more durable remedy — **a hybrid surface enhancement that integrates tiny cone structures with a graphene oxide coating** has the potential to transform our approach to frost prevention, ensuring surfaces remain frost-resistant for over 150 hours. This innovative method prolongs the frost-free operational duration by an impressive 1000 times compared to existing techniques, positioning it as a revolutionary solution for both daily and industrial use.

### Existing Obstacles in Frost Mitigation

Traditional anti-frost techniques, such as superhydrophobic coatings (which repel water) or lubricant-infused surfaces (which reduce ice formation through a lubricating layer), present solutions but only for limited periods. Additionally, these methods encounter further challenges, including vulnerability to scratches, degradation over time, and contamination from environmental debris like dust and particles, which undermine their efficiency. Such techniques can be delicate, fragile, and ill-suited for long-term or large-scale applications. In areas that frequently encounter frost or in sectors where frost management is crucial (such as aerospace, energy, and communications infrastructure), a durable and effective solution is urgently needed.

### Innovation in Anti-Frost Solutions: Tiny Cones and Graphene Oxide

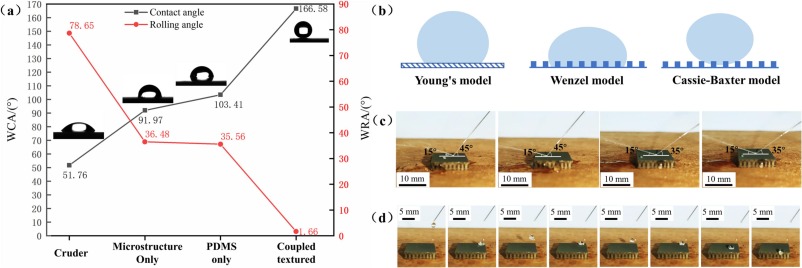

Researchers have recently presented a compelling alternative by merging microstructural innovations with advanced coatings. The method begins with the incorporation of **millimeter-scale cone-shaped structures** onto a surface — these miniature cones, which can be fabricated from various materials (like metals or polymers), alter the way frost forms. A key structural aspect of this approach is the valleys situated between the peaks of the cones, where a **600-nanometer thick layer of graphene oxide** is deposited. This combination yields several outstanding properties:

1. **Sacrificial Frost Formation on Peaks:** The design of the cones encourages frost to accumulate primarily at their tips, thereby generating “sacrificial frost areas.” This prevents frost accumulation in the flatter valleys between the peaks, keeping broader surface areas clear of frost.

2. **Hygroscopic Graphene Oxide Layer:** Graphene oxide proves to be an exceptionally effective hygroscopic material, meaning it captures moisture from the environment. When coated in the valleys between the tiny cone structures, this layer helps maintain undersaturated conditions in the flat enclosed areas, further inhibiting frost development. In essence, the surface effectively manages water vapor and moisture distribution in a manner that suppresses frost formation for extended periods.

### Resilience and Durability in Extreme Conditions

This groundbreaking surface modification has undergone extensive testing. In controlled settings with high humidity and temperatures as low as **-12°C**, surfaces treated with cone structures and the graphene oxide coating resisted frost for up to **160 hours**. In comparison, conventional approaches such as superhydrophobic and lubricant-infused surfaces only managed to inhibit 5-36% of frost formation, illustrating their comparatively brief effectiveness.

A major advantage of this new technique is its durability under real-world conditions. Not only does the surface withstand frost for extended intervals, but it is also **exceptionally resistant to scratches, cracks, and contamination.** The testing environment included not just surface scratching but also exposure to contaminants like plastic particles, and despite this, the frost-resistant characteristics remained intact, establishing it as a **robust alternative for outdoor infrastructure.**

The team demonstrated that the technique could be implemented over large areas by producing **hexagonal patterns** of graphene oxide-coated cells made from materials like **aluminium**, **polydimethylsiloxane (PDMS)**, and even **plastics** — broadening its applicability to various practical scenarios.

### Implementation and Future Prospects

The potential use cases for this technology are extensive. In cold, humid climates, this technique could be integrated into infrastructure, transport systems, and energy systems that require clean surfaces, such as solar panels and power lines. Aerospace engineering and wind turbine technology could also reap the benefits of this durable surface modification, potentially mitigating expensive delays or technical challenges linked to frost formation.

One intriguing future avenue for this technology could involve the integration of **active de-icing mechanisms.** The research team behind this innovation speculates that introducing an element with low interfacial toughness on the cone peaks could further optimize frost management. The peaks, which collect “sacrificial frost” in the current design, could potentially be easily de-iced or have frost eliminated with minimal energy or chemical intervention, enhancing both the longevity and maintenance-free characteristics.