An innovation in eco-friendly adhesive technology has emerged, tackling the widespread compromise between environmental sustainability and effectiveness. Historically, sustainable adhesives have had difficulty equaling the strength and adherence of traditional products, frequently leaving residues or necessitating extreme conditions for recycling. Nevertheless, a recent advancement led by a group of chemists employs groundbreaking reversible adhesive technology, offering a remedy to these challenges.

The new adhesive harnesses the reversible chemistry inherent in vitrimers, a category of structures recognized for their dynamic and flexible bonding capabilities. These structures have previously inspired a wave of recyclable adhesive products, including those used in typical consumer items. Notably, Carlsberg has adopted such adhesives to connect beer cans as a substitute for plastic rings, while Apple has integrated electro-responsive polymers into their devices to improve reparability.

At the core of this innovation is alpha-lipoic acid, an organosulfur compound celebrated for its eco-friendly potential. Researchers have merged this compound with pentaerythritol in a unique one-pot process, resulting in a polymer precursor with impressive attributes. The adhesive quickly cures under violet light, establishing a strong bond with various materials such as glass, aluminum, and polycarbonate, as well as FR4, a composite common in electronics.

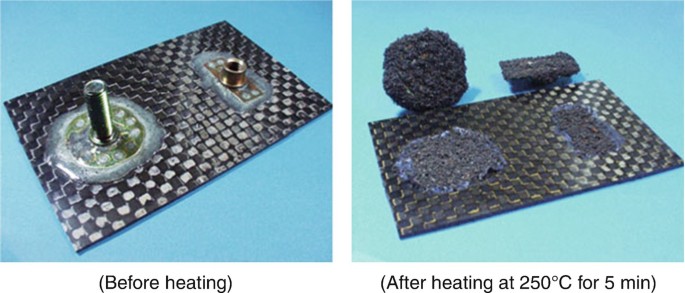

One of the remarkable aspects of this adhesive is its reversibility. It can be readily unbonded and prepared for recycling using a microwave stimulus lasting merely 30 seconds, eliminating the requirement for harsh solvents. The microwave irradiation process alters the carbon-sulfur bonds, inducing depolymerization while maintaining the adhesive’s qualities through multiple recycling cycles.

Moreover, the adhesive exhibits considerable water resistance, a crucial property for use in humid environments. The polymerization reaction remains effective even underwater, sustaining comparable shear strength to that produced under dry conditions. Tests performed on chicken skin, serving as a surrogate for human skin, demonstrated the adhesive’s superior performance compared to other lipoic-acid-based products and comparable strength to commercial cyanoacrylate adhesives.

This groundbreaking adhesive represents a significant shift toward more sustainable options in both household and industrial applications. By eliminating the need for harsh chemicals and energy-intensive recycling methods, this innovation not only aligns with environmentally friendly practices but also enhances the functionality and adaptability of adhesives across diverse settings and conditions.