Engineers developing fuel cells for heavy-duty trucks have traditionally believed they understood the problem’s location: a persistent, slow phase in the oxygen reduction reaction that restricts the rate at which hydrogen transforms into electricity. The general idea is that by creating a better catalyst to hasten that phase, cleaner energy for ships, industrial systems, and long-haul transportation can be achieved. However, new findings from the Fritz Haber Institute reveal that this bottleneck is not stationary. It shifts continuously as operational conditions change.

The oxygen reduction reaction, or ORR, occurs through several chemical steps at the fuel cell cathode. For many years, researchers have tackled this complexity by pinpointing the single slowest step and optimizing catalysts accordingly. But when Sebastian Öner’s team examined platinum, iridium, ruthenium, and rhodium nanoparticles under the extreme pressures and voltages encountered in functioning fuel cells, they found a more complex situation: the rate-limiting step varies based on the electrical intensity applied and the oxygen pressure. Different steps alternate in causing slowdowns. The catalyst surface itself undergoes both chemical and structural evolution as conditions vary, effectively altering the benchmarks for the reaction intermediates.

This is more than just a lab phenomenon. Fuel cells used in real-world applications operate under diverse loads, temperatures, and pressures. If fundamental kinetics change across this spectrum, designing catalysts based on a single fixed bottleneck involves optimizing for conditions that may exist only temporarily, if at all.

## What Transpires When the Surface Adjusts

To observe these dynamics, the team utilized membrane electrode assemblies instead of conventional liquid electrochemical cells, increasing oxygen pressure to six bar while methodically monitoring temperature and applied voltage. They discovered that at low electrical bias, the reaction rate is influenced by both the energy barrier for the chemistry and the organization of water molecules around the catalyst. The metal surface is dynamic. Oxygen molecules vie for space against a layer of water-generated species like hydroxide, and the surface itself either releases or gathers oxygen-containing molecules as voltage fluctuates.

On platinum catalysts, the energy necessary for the reaction reached its peak at precisely the same voltage at which the metal surface underwent a chemical transformation, losing its oxygen layer. This pseudo-capacitive mechanism serves as a gatekeeper, determining conversion efficiency. Increasing voltage proved significantly more effective than raising pressure at accelerating the ORR, highlighting a vital benefit of electrochemical systems: electrical bias can reorganize reaction pathways directly, rather than depending on sheer compression.

> “The conventional perspective within the community is that multi-step reactions can be distilled into one rate-determining intermediate, or in more precise terms, that the extent of rate control of this step equates to one. Nevertheless, our results contest this notion.” – Sebastian Öner, Fritz Haber Institute of the Max Planck Society

The researchers also determined the reaction’s rate constant by altering pressure, demonstrating that pressure does more than merely provide additional oxygen. It fundamentally alters the speed at which molecules react. However, increased pressure did not shift the electrical potentials at which critical kinetic changes occurred. This stability suggests a deeper limitation: what occurs at the delicate interface between solid catalyst and liquid electrolyte creates fundamental performance boundaries, irrespective of how much reactant is introduced.

## Designing for Complexity Rather Than Averaging It Out

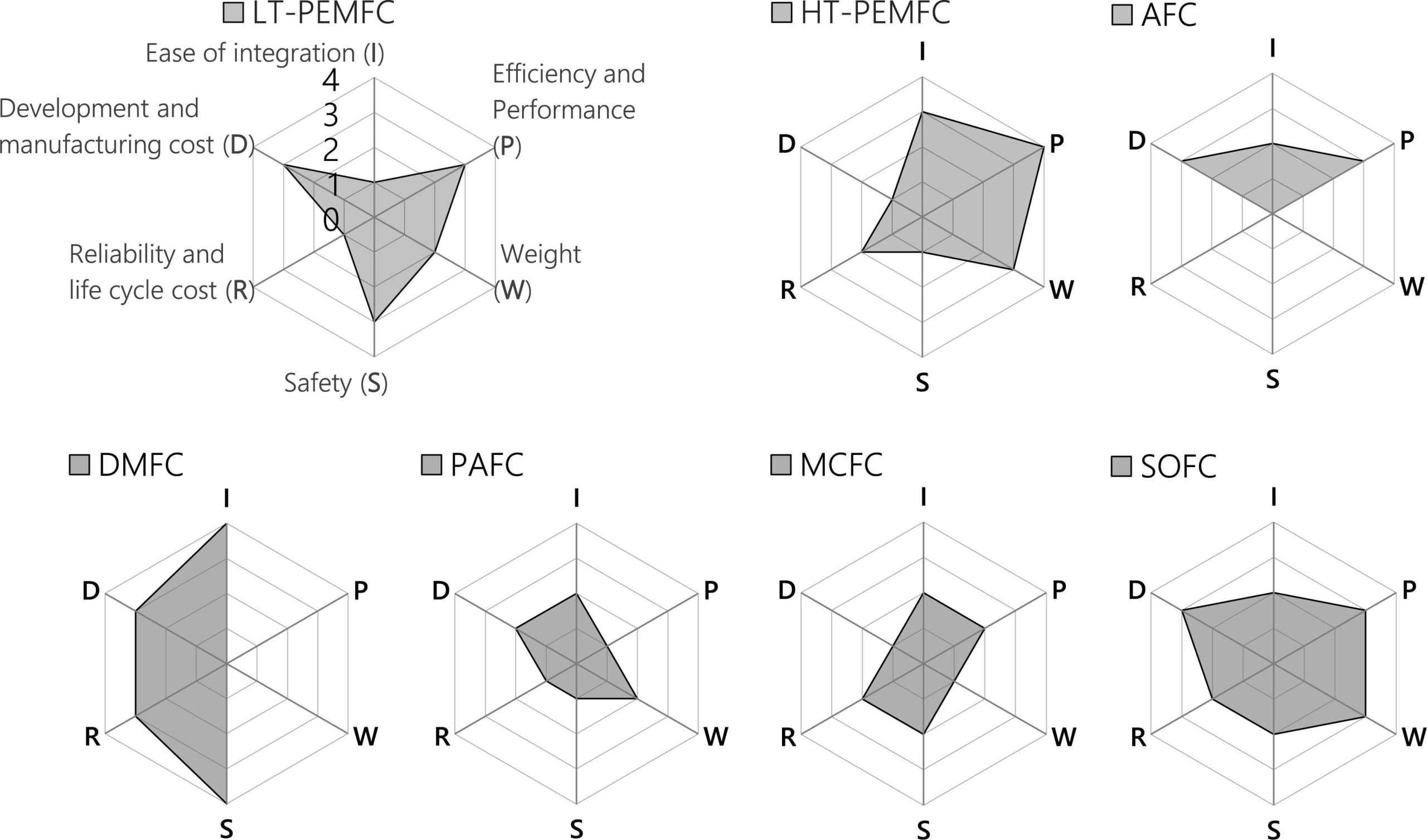

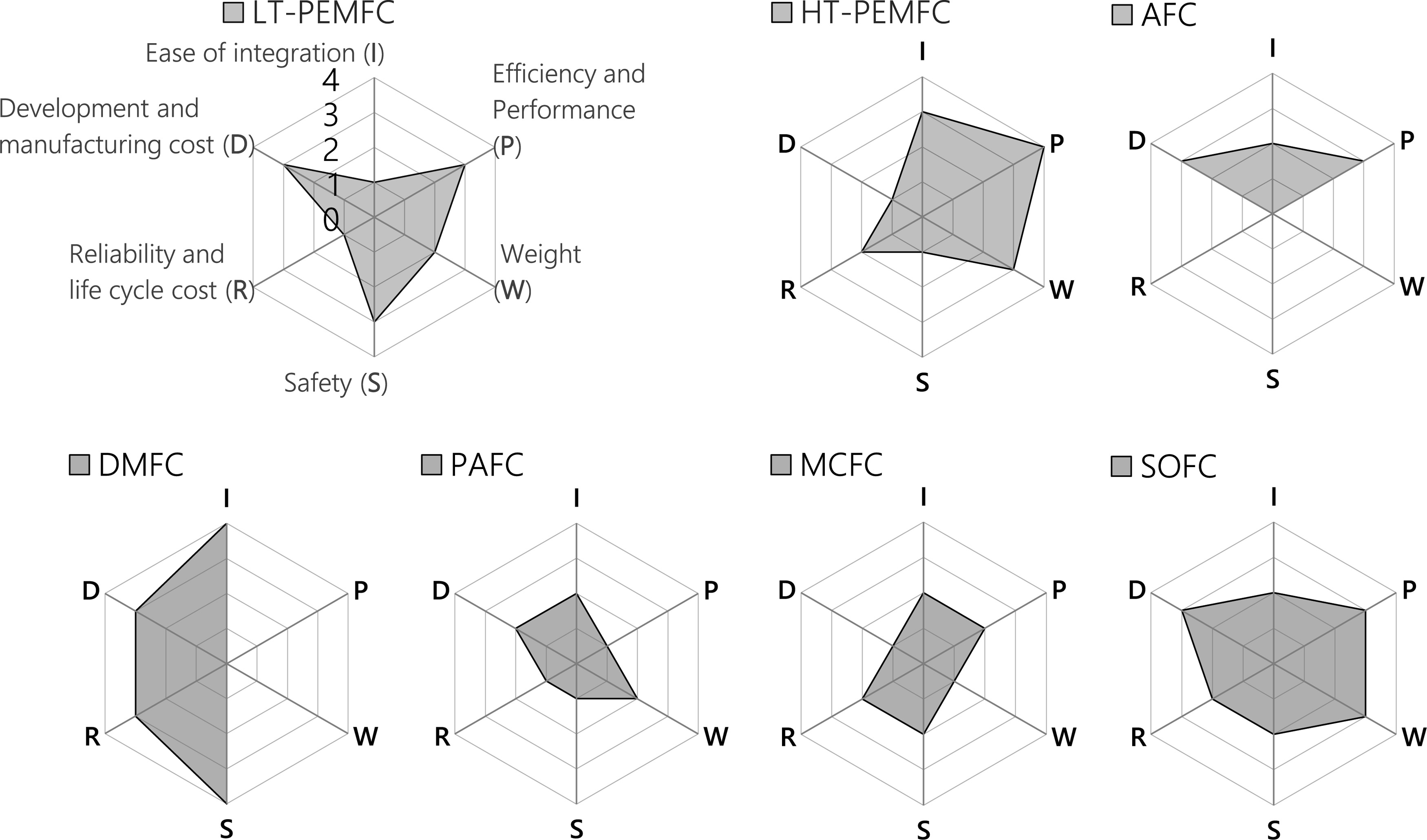

Across all four catalysts, neither activation energy nor reaction frequency alone clarified why certain materials perform better. Performance arose from the interaction of those factors as conditions evolved. The optimal catalyst is not the one that merely diminishes a single barrier, but one that successfully navigates an entire series of fluctuating challenges.

The ramifications extend beyond fuel cells. Reducing carbon dioxide, splitting water, and other multi-step electrochemical reactions also feature dynamic interfaces. Assuming a single rate-determining step in these systems might disguise the genuine physics governing efficiency. For technologies required to operate at elevated current densities and industrial pressures, comprehending this kinetic cascade may be crucial for translating laboratory findings into robust devices.

The study establishes a framework linking decades of microscopy observations to the actual mathematics of energy conversion. By charting how kinetic control shifts with voltage and pressure, it outlines a new research agenda, one that embraces the complex reality of functional catalysts rather than simplifying them into manageable models. Whether this approach will lead to advancements in catalyst design remains uncertain, but it’s now evident that the previous map overlooked vital terrain.

[Nature Communications: 10.1038/s41467-025-67494-x](https://doi.org/10.1038/s41467-025-67494-x)