A pilot project has succeeded in scaling-up production of hydrogen using solar power, opening the door for the technology to be used in the battle against climate change.

Hydrogen has long been touted as a possible carbon-neutral fuel source that could be used to transition away from more polluting alternatives, such as oil and gas. It can be burned cleanly, and 1kg of hydrogen gas has the same energy as around 2.8kg of petrol, meaning it could be highly efficient. However, scientists have struggled to find a way to produce hydrogen in bulk using technologies that don’t have their own hefty carbon footprint. Currently, most hydrogen is produced via gas or steam reforming – classed as ‘brown’, ‘grey’ or ‘blue’ depending on the method used. A more environmentally friendly way, dubbed ‘green’ hydrogen, is to use electrolysers to split water – effectively carbon-neutral – but this requires a tremendous amount of energy, and previous efforts have struggled to deliver this using renewable sources, such as solar, wind or geothermal power.

Solar power projects in particular are difficult to scale up, and are usually limited to systems of less than 100W, although the technology has been used to create so-called ‘solar fuels’ before. Last year, kerosene was synthesised using a solar array near Madrid, Spain, in the hope of creating carbon-neutral fuels for the aviation industry. Now, a team from the Swiss Federal Institute of Technology (EPFL) in Lausanne, Switzerland, has announced success in using solar arrays for the production of hydrogen on the kilowatt-scale, providing another fuel option.

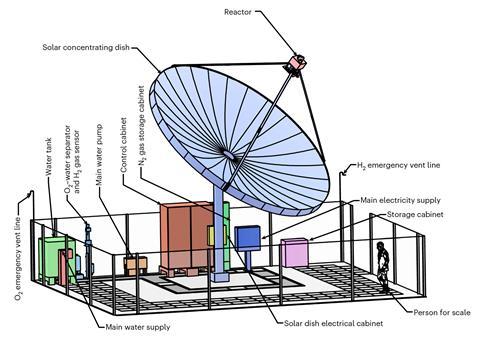

The group, led by Sophia Haussener, used a sun-tracking, oversized solar dish that was capable of concentrating light to the equivalent of 800 suns. This was then coupled to a photo-electrochemical device that integrated all the key requirements of converting the solar rays into electricity, as well as an electrolyser and water-based heat exchanger, which could be used to split water to produce hydrogen and oxygen. This was trialled for 13 days in August 2020 and between February and March 2021. The team managed to achieve a maximum rate of around 1.36g of hydrogen per minute, equivalent to 2.97kW of fuel, and a total of 3.2kg of solar hydrogen throughout the entire trial. After allowing for the standard energy loses that are usual with solar technology, the team reported a solar-to-hydrogen efficiency of more than 20%. The team’s work also includes their data on thermal management and optimisation of the system, allowing other groups to trial the technology and maximise energy conversion.

Although there is a long way to go before such technology could be used in our homes – particularly as hydrogen is difficult to store at standard temperatures and pressures – the work demonstrates the technical feasibility of such devices, says Aldo Steinfeld, a professor at ETH Zurich, Switzerland and expert in solar fuels. ‘Moving from the laboratory to the field is a critical phase in technology development,’ he adds. ‘The authors have successfully accomplished this phase by demonstrating the on-sun operation of the entire solar fuel system at the kW scale under real, intermittent solar irradiation conditions. The findings are relevant for the large-scale implementation of the technology.’

The announcement comes as the race for synthetic, carbon-neutral fuels moves out of the lab and into the real world. In December 2022, Porsche opened a synthetic fuel and green hydrogen plant in southern Chile, where high winds and good sunlight provide ideal energy conditions to power the facility. Currently, the plant aims to produce 130,000 litres of e-fuel by the end of 2023, growing to 55 million litres a year for the German automotive market. The Saudi Arabian megacity Neom, currently under construction, has also announced plans for the entire project to be powered using green hydrogen.