**Improving MOF Databases: A Neural Network Method for Error Detection and Classification**

Metal–organic frameworks (MOFs) represent promising materials utilized across various applications, spanning from gas storage to catalysis. Nonetheless, the dependability of computational forecasts related to these materials significantly hinges on the accuracy of the foundational crystal structure databases. Recent progress in neural network technologies provides a means to enhance database precision by pinpointing and categorizing structural errors.

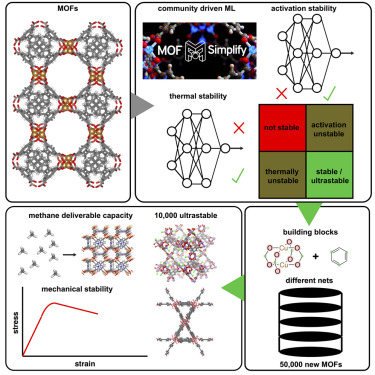

Researchers from the University of Ottawa, under the guidance of PhD candidate Marco Gibaldi and his advisor Tom Woo, have engineered a neural network that offers considerable advancements in the precision of MOF databases. This neural network is intended to identify and highlight entries featuring frequent structural errors, including proton omissions, charge imbalances, and crystallographic disorders. If left unaddressed, these errors could compromise the trustworthiness of predictions derived from these databases.

Gibaldi encountered the reliability challenges of databases directly when a MOF, which predictive software indicated to be a leading candidate, failed to demonstrate anticipated properties during experimental evaluation. The discrepancy was later attributed to errors in the simulated crystal structure, underscoring the need for an improved error detection system.

The team meticulously assembled a dataset comprising 11,000 MOFs, diligently spotting errors in each structure. This exhaustive endeavor established the groundwork for training a graph attention neural network. The model was subsequently evaluated against various databases, showcasing an impressive capability to classify as much as 96% of errors, surpassing existing feature-based models.

Yongchul Chung, a computational materials scientist at Pusan National University, mentioned that this instrument can significantly conserve researchers’ time by proactively identifying flawed structures. Moreover, the study highlights the critical role of reliable data in machine learning models, emphasizing that the precision of predictions is solely as reliable as the datasets upon which they are built.

As Woo’s team continues to enhance their methodology, they aim to refine the graph representations of crystal structures and expand the range of errors that can be detected. This tool not only strives to unify computational and experimental research but also to bolster confidence in the computational research community and its related datasets. Such developments could enable more accurate and trustworthy material discoveries, narrowing the divide between theoretical predictions and experimental outcomes.