A synergistic strategy for nanofabrication has allowed scientists to create intricate 3D structures from nearly any material at a nanoscale. The innovative method merges traditional two-photon polymerization (2PP) nanoprinting with laser-guided optofluidic assembly, leveraging the advantages of both techniques to establish a flexible and multi-material fabrication system.

Nanostructures frequently display unique attributes in comparison to their bulk counterparts, as surface and interface interactions dominate the chemical behaviour of the materials involved. These remarkable characteristics have led to diverse applications extending beyond nanoengineering into areas such as medicine, robotics, and catalysis. Nonetheless, limitations regarding the selection of appropriate materials and the adaptability in shaping and geometry persist as significant obstacles in the creation of more intricate and versatile nanodevices. While two-photon polymerization offers a high-resolution 3D printing alternative, it is predominantly restricted to highly specialized polymers. On the other hand, self- or directed-assembly accommodates a broader range of substrates but encounters challenges with freeform shaping and achieving high yield.

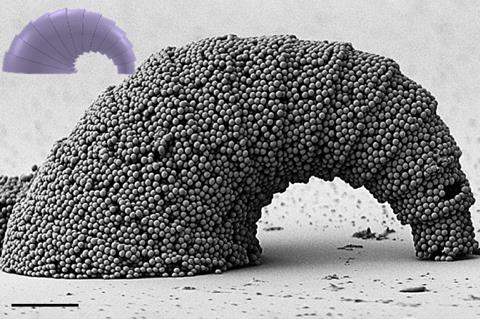

By segmenting the fabrication process into two distinct phases, Mingchao Zhang and his global team have successfully united the strengths of these methods. Initially, the team crafted the outline of the desired nanounit, producing a precisely shaped hollow 3D template via 2PP. This mold is subsequently immersed in a nanoparticle suspension—including metal oxides, carbon nanomaterials, and quantum dots—while the team directs a femtosecond laser at the opening of the template to initiate assembly. The laser pulse generates a localized thermal gradient that prompts the nanoparticles to flow into the mold where they conform to the design from the 2PP phase. A subsequent post-processing step involves the removal of the outer casing, resulting in a free-standing 3D structure composed of the selected material.

“This separates geometry from chemistry,” states Zhang, affiliated with the National University of Singapore. “Our approach maintains broad compatibility since we are not dependent on a specific photochemistry to generate the final structure. Rather, the laser facilitates transport and confinement-driven packing, making the primary requirement that the material can exist as a stable dispersion of particles.”

This comprehensive technique additionally allows for sequential multi-material fabrication, paving the way for the development of more intricate, multi-functional devices. “Once one material is densely packed inside its templated area, it achieves mechanical and energetic stability,” remarks Zhang. “Following that, we can eliminate surplus particles, transition to a different particle suspension, and assemble the next material in a different region or segment, all without mixing the previously used particles.”

To illustrate the possibilities offered by this novel method, the team produced a series of mixed-material microdevices, encompassing valves capable of sorting nanoparticles of varying sizes, as well as light-driven microrobots that may find applications in sensing and bionics.

The flexibility of this integrated approach has captured the attention of other researchers within the discipline. “In contrast to other concepts that necessitate tailored resins, this research unveils a novel dimension for 3D printing that provides its own pathway for versatile multi-material manufacturing,” comments Jonathan Fan, an optical engineer from Stanford University. “The assembly of nanoporous materials, in particular, holds broader implications for membrane-based devices and systems.”

“The theoretical framework is truly remarkable. The authors skillfully examined the key forces driving particle assembly and offered compelling experimental evidence to bolster the theory,” notes Xiaoxing Xia, a nanofabrication scientist at the Lawrence Livermore National Laboratory. “The proof-of-concept devices are intriguing and motivate readers to innovate. I believe the next phase will involve identifying the appropriate applications for this methodology.”

Zhang and his team have already begun exploring how reaction parameters, including solvent and surfactant selection, affect the speed and stability of the fabrication process and continue to refine the theoretical foundation supporting the method. “I aim to develop predictive design principles that link solvent choices, particle interactions, flow dynamics, and template geometry, enabling the process to be programmable rather than reliant on empirical methods,” he explains.